Understanding Gear Oil: What You Need to Know for Optimal Performance

Gears are the backbone of countless machines, from your car to industrial equipment. But what keeps them running smoothly? The answer lies in gear oil. Let’s dive into why it’s essential and how it ensures optimal performance.

Why Gear Oil Matters?

Without proper lubrication, gears would overheat, wear down, or even seize up. Gear oil acts like a shield, reducing friction and wear while ensuring efficiency.

The Basics of Lubrication

Lubrication minimizes metal-to-metal contact, preventing damage. Gear oil also carries away heat, maintaining a safe operating temperature.

What is Gear Oil?

Definition and Composition

Gear oil is a specialized lubricant formulated to protect gears under extreme pressure and temperature conditions. It typically contains a base oil and various additives.

Types of Gear Oil

Mineral-Based Gear Oil

Made from refined crude oil, it’s cost-effective and suitable for standard applications.

Synthetic Gear Oil

Engineered in labs, synthetic oils excel in extreme conditions, offering superior performance and longevity.

How Gear Oil Works?

The Role of Viscosity

Viscosity determines how well oil flows. Thick oil ensures protection under high pressure, while thinner oil works better in colder environments.

Additives and Their Importance

Additives enhance gear oil performance. They can reduce wear, resist oxidation, and prevent rust.

Key Functions of Gear Oil

Reducing Friction

By creating a thin film between gear surfaces, friction is minimized, enhancing efficiency.

Cooling Mechanism

Gear oil dissipates heat generated during operation, protecting components from thermal damage.

Protection Against Wear and Tear

It forms a barrier against corrosion, extending the life of your machinery.

Common Applications of Gear Oil

Automotive Industry

From manual transmissions to differentials, gear oil is vital for smooth vehicle operation.

Industrial Machines

Heavy-duty equipment like conveyor belts and crushers rely on gear oil for uninterrupted functionality.

Marine Equipment

Gear oil protects components in harsh marine environments, ensuring reliability and safety.

Choosing the Right Gear Oil

Consider Equipment Specifications

Always refer to the manufacturer’s recommendations for compatibility.

Understanding API Ratings

API ratings indicate oil quality and performance. Look for the right grade for your equipment.

Matching Temperature and Pressure Requirements

Choose oil that performs well under the conditions your machinery operates in.

Signs of Gear Oil Problems

Overheating Gears

Excessive heat might mean the oil isn’t doing its job.

Noise or Vibration

Unusual sounds can indicate insufficient lubrication or worn-out oil.

Leaks and Contamination

Visible leaks or cloudy oil often signal contamination or degradation.

Benefits of Regular Gear Oil Maintenance

Improved Performance

Fresh oil keeps machinery running smoothly and efficiently.

Prolonged Equipment Lifespan

Proper lubrication reduces wear, extending the life of gears and components.

Reduced Costs

Maintenance prevents costly repairs or replacements down the line.

How to Change Gear Oil

Tools You’ll Need

Gather a wrench, drain pan, new gear oil, and a funnel.

Step-by-Step Process

Locate the drain plug and place a pan underneath.

Remove the plug to drain old oil.

Reinstall the plug and fill with new oil.

Check the level and adjust as needed.

Common Myths About Gear Oil

Synthetic Oils Always Outperform Mineral Oils

While synthetic oils excel in extremes, mineral oils can perform just as well in standard conditions.

All Gear Oils Are the Same

Different applications require specific formulations—choosing the wrong one can be disastrous.

Conclusion

Gear oil is the unsung hero of countless machines. By understanding its importance and maintaining it properly, you can ensure optimal performance and longevity for your equipment. Hydraulic pump oil is essential for the smooth operation of hydraulic systems, providing the necessary lubrication and pressure transmission. Choosing the right Hydraulic Pump Oil can significantly impact the efficiency and lifespan of your hydraulic equipment.

FAQs

How often should I change gear oil?

It depends on the application. Consult your equipment manual, but typically every 30,000-60,000 miles for vehicles.

Can I mix different types of gear oil?

No, mixing oils can compromise performance and lead to issues.

What happens if I use the wrong gear oil?

Using the wrong oil can cause overheating, wear, and potential equipment failure.

How can I tell if gear oil is contaminated?

Cloudiness, discoloration, or a burnt smell are clear signs of contamination.

Are additives necessary for gear oil?

Yes, additives enhance protection, reduce wear, and improve overall performance.

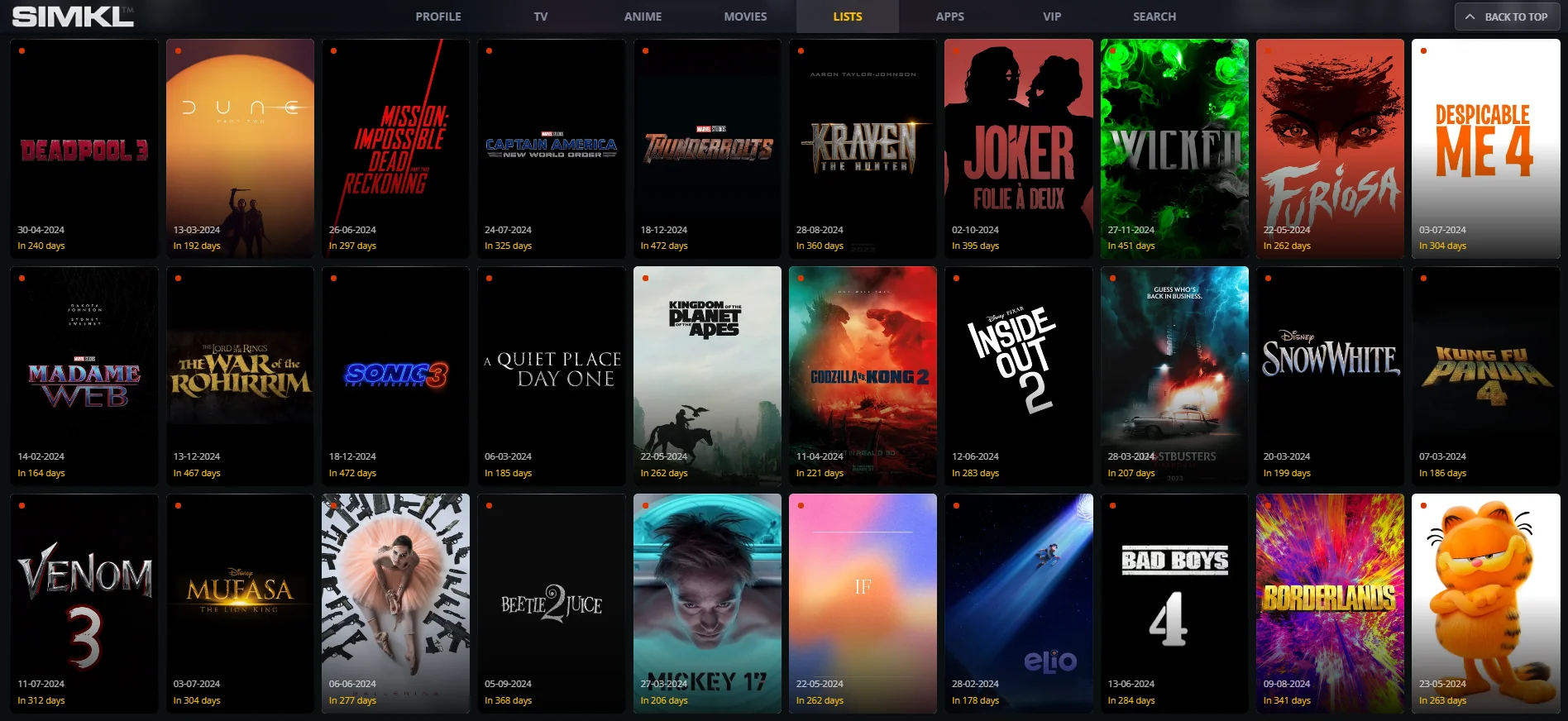

What's Your Reaction?